Automatic vs Semi-Automatic Water Filling Machine – Full Comparison

Choosing the right water filling machine is one of the most important decisions when starting or upgrading a water bottling plant. The two most common options are Automatic and Semi-Automatic Water Filling Machines. Each has its own advantages, costs, and ideal use cases.

In this detailed comparison, we will help you understand the differences so you can select the best machine for your business needs.

What is a Semi-Automatic Water Filling Machine?

A semi-automatic water filling machine requires partial manual operation. Operators manually place bottles, start the filling process, and sometimes handle capping separately.

Key Features:

- Manual bottle loading and unloading

- Basic control system

- Lower production speed

- Requires skilled manpower

Best For: Small-scale plants, startups, and low-budget operations.

What is an Automatic Water Filling Machine?

An automatic water filling machine performs rinsing, filling, and capping automatically with minimal human intervention. Bottles move through the system using conveyors.

Key Features:

- Fully automatic operation

- Integrated rinsing, filling & capping

- High production capacity

- Consistent filling accuracy

Best For: Medium to large-scale water bottling plants aiming for high output.

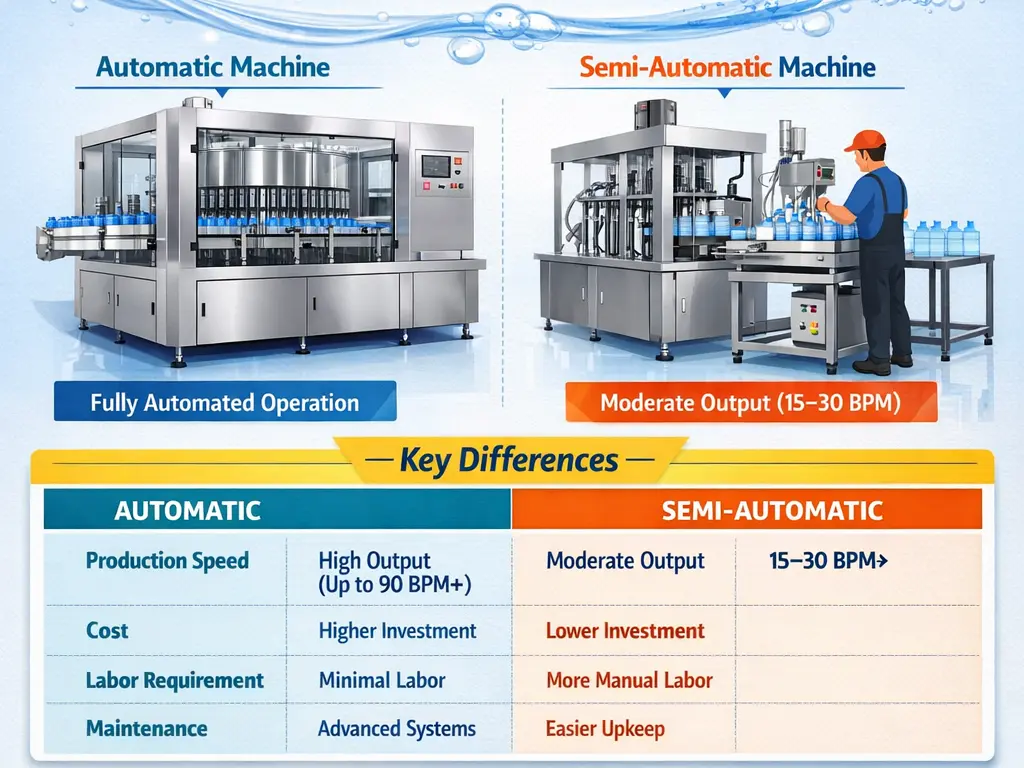

Automatic vs Semi-Automatic – Comparison Table

| Feature | Semi-Automatic Machine | Automatic Machine |

|---|---|---|

| Production Capacity | Low to Medium | Medium to High |

| Manpower Required | High | Very Low |

| Initial Investment | Low | Higher |

| Filling Accuracy | Moderate | High |

| Operating Speed | Slower | Faster |

| Maintenance | Simple | Moderate |

| Scalability | Limited | Excellent |

Production Capacity Comparison

- Semi-Automatic: Suitable for 300–800 bottles per hour

- Automatic: Ranges from 1000 BPM to 6000+ bottles per hour depending on model

If your target is high-volume production, automatic machines are clearly the better choice.

Cost Comparison

- Semi-Automatic Machine Cost: Lower upfront cost, ideal for startups

- Automatic Machine Cost: Higher initial investment but better long-term ROI

While semi-automatic machines are budget-friendly, automatic machines reduce labor costs and increase productivity over time.

Maintenance & Operating Ease

Semi-automatic machines are easier to maintain due to simpler mechanisms. Automatic machines require scheduled maintenance but deliver stable performance when maintained properly.

Chahith Engineering designs machines using SS 304 stainless steel, ensuring durability, hygiene, and long service life.

Which Machine Should You Choose?

Choose Semi-Automatic if:

- You are starting a small water bottling business

- Budget is limited

- Production demand is low

Choose Automatic if:

- You want high production capacity

- You aim to scale your business

- You want consistent quality with minimal manpower

Why Choose Chahith Engineering?

- High-quality SS 304 machines

- Customized solutions based on capacity

- Pan-India installation & support

- Reliable after-sales service

Conclusion

Both automatic and semi-automatic water filling machines have their place in the industry. The right choice depends on your budget, production goals, and future expansion plans.

If you are unsure which machine suits your requirement, Chahith Engineering is here to help you make the right decision.

👉 Get a Free Consultation | Request a Quote Today