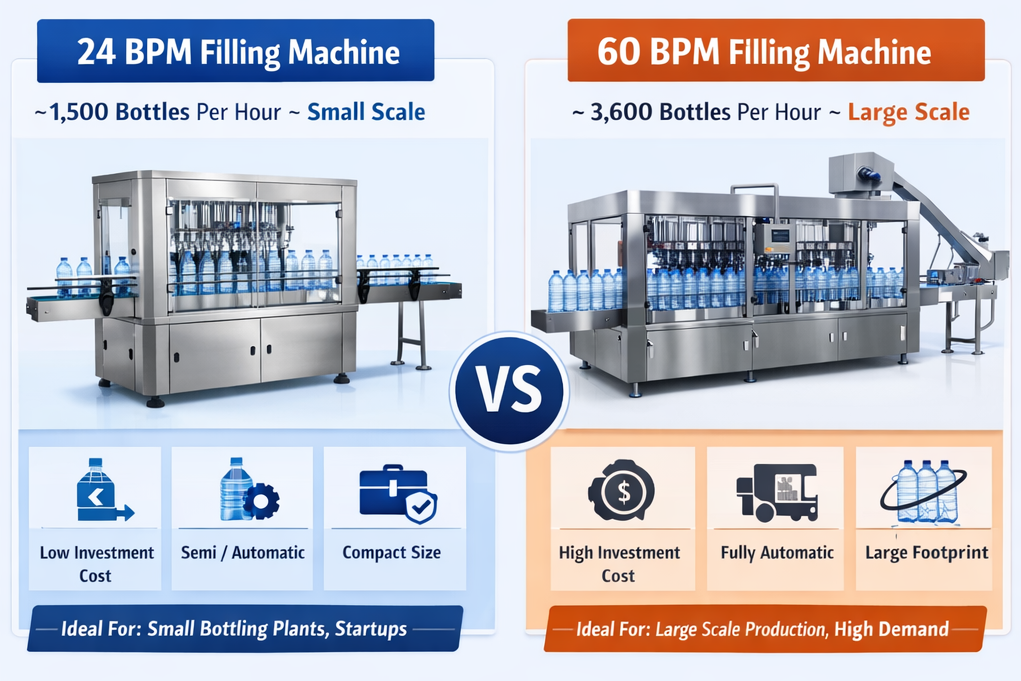

24 BPM vs 60 BPM Filling Machine: Which One Is Right for Your Bottled Water Business?

24 BPM vs 60 BPM Filling Machine: Which One Is Right for Your Bottled Water Business? Choosing the right capacity is crucial, and the comparison of 24 BPM vs 60 BPM filling machine setups helps bottled water businesses make better investment decisions. for any bottled water plant. Two of the most commonly used capacities in the Indian market are 24 BPM (Bottles Per Minute) and 60 BPM filling machines. While both serve the same purpose—accurate, hygienic, and efficient bottle filling—their application, output, and investment requirements are very different. In this blog, we compare 24 BPM vs 60 BPM filling machines to help you choose the best option for your production needs. Benefits of 24 BPM vs 60 BPM Filling Machines for Bottled Water Plants 24 BPM machines are ideal for small water plants due to low investment, simple operation, and minimal maintenance. Meanwhile, 60 BPM machines offer higher productivity, better automation, and lower cost per bottle, making them suitable for growing bottled water businesses needing faster output 24 BPM vs 60 BPM Filling Machine — Understanding BPM BPM (Bottles Per Minute) refers to the number of bottles a machine can fill in one minute under standard operating conditions. Higher BPM means higher production capacity, but it also involves higher cost, space, and operational planning. 24 BPM Filling Machine: Overview A 24 BPM water filling machine is ideal for small to medium-scale bottled water plants or startups entering the packaged drinking water industry. Key Features Advantages Limitations Best For 60 BPM Filling Machine: Overview A 60 BPM filling machine is designed for medium to large-scale production units where speed, automation, and consistency are critical. Key Features Advantages Limitations Best For 24 BPM vs 60 BPM: Quick Comparison Table Feature 24 BPM Machine 60 BPM Machine Production Capacity ~1,500 bottles/hour ~3,600 bottles/hour Automation Level Semi / Automatic Fully Automatic Investment Cost Low Medium to High Power Consumption Low Moderate Space Requirement Compact Larger Ideal Business Size Small Medium to Large ROI Speed Moderate Fast Which Filling Machine Should You Choose? The choice between a 24 BPM and 60 BPM filling machine depends on your business goals, market demand, and budget. Final Thoughts Both 24 BPM and 60 BPM water filling machines play an important role in the bottled water industry. Understanding your current requirements and future expansion plans is key to making the right decision. Investing in the correct capacity ensures smooth operations, better efficiency, and long-term success. At Chahith Engineering, we manufacture high-quality SS 304 water bottle filling machines with reliable performance, pan-India installation, and after-sales suppor